Innovation 1

In terms of safety, the system is designed to comply with the International standard EN61508 SIL3 level, a must for software controlled dynamic overhead operations. It meets the BGV-C1 requirements as specified in DIN56925/56950.

Innovation 2

The CC48 / R8CPU-VS controller is a universal motion-control system, not only capable of controlling the new generation Stagemaker variable speed hoists, but could be used also in conjunction with standard single or double speed Stagemaker hoists, provided they are equipped with an position encoder.

Innovation 3

The system design is modular and could be easily extended up to 8 individual R8CPU-VS racks. Each R8CPU-VS rack is able to operate hoists in depended from the CC48 operating desk. This means that if needed, in case of manual operations or a brake down of the operating system, it still is possible to run the hoists without the use of the operating desk.

Innovation 4

Precise and repetitive precision is achieved by using a two channel incremental encoder. This encoder is a robust shock proof one, built-in the hoist on the loadwheel shaft. In case of variable speed hoists version V, a separate encoder on the motor shaft provides overspeed detection for safety purposes.

Advantage

The system is designed on the starr connection principal using only one multi core (Harting 16p) cable between every hoist and the controller. Since there is no intelligence at hoist level, hoists easily could be added or removed from a configuration or connected to another controller channel if needed.

Hoist requirements:

For controlling and positioning, the hoist must be equipped with contactors and positioning encoder. The following combinations are possible:

R8CPU-VS controllers comply to today’s advanced safety requirements, in terms of group related safety functions such as main-contactor, emergency over travel limits, overload and under load protection. The control software includes the coverage of all safety features and commands using separate and parallel processors.

These safety features are required by law in an increasing number of European countries and refer in particular to cases of non-secured moving objects above performers, audiences or any other open public location.

In most other countries, these strong recommendations are not required by low but still advised by safety authorities.

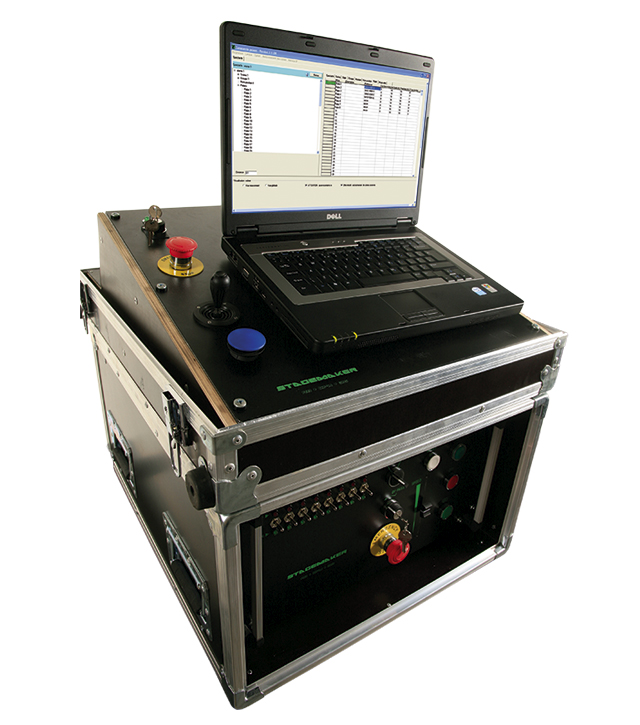

Since some safety regulations require a hard wired emergency circuit, R8CPU-VS controllers are quipped with an independent operating intervention facility. The PC and the racks are linked through a separate cable that interconnects the E-stop and relevant safety functions of all controllers in charge. It enables the user in case of emergency to stop all connected hoists in one action, no matter the motion was a programmed or manual. At the same time, it allows the operator to combine other manual functions as “RUN” button, and selector switch for Local/remote and By-pass.

The operating desk CC48 is equipped with a power full Windows XP based laptop with pre-installed R8CPU-VS operating software, doesn’t allow the operator to install other than this dedicated operating software. It also is not possible to download or to run other programs from the CD drive.

The R8CPU-VS racks are through an RJ45 cable connected with the hub at the backside of the desk and as such a network configuration is realized.

With the computer you are able to set positions, program and save scenes, and control the show. The computer sends the data via the hub to the connected racks.

Software (free of charge)

Easy tree-structures and intuitive system design are being used to minimize the learning time. The software and its updates are free of charge and continuously in the process of development. It will be available for download from the Stagemaker website once released.

The programming language C++, Windows XP is only used for visualization purposes.

Possible operation examples (with variable speed hoists version V):

Note: The software development is an ongoing process and limitations are to be considered in particular in terms of complex operations using multi point suspensions on one rigid (truss) object !